Aydınsan Makina

About Us

Our adventure, which we started in 2008 with our slogan “WE ADDED INTELLIGENCE TO STEEL”, continues as the largest aluminum extrusion mold manufacturing company in Turkey and Europe. AYDINSAN MAKİNA, our chairman of the board, Mr. it was founded by İsmail AYDIN at the beginning of 2008. it has become one of the leading companies in the sector with our management that follows the innovations and technology we have brought to the sector with a devoted and customer-oriented production approach.

“AYDINSAN MAKİNA”, which is the choice of many of our customers at home and when leaving, moved to its new location, built as 19,000 mı open and 4,500 mı closed area, in February 2023. By closely following technology, we maintain our complementary leadership quality with our latest system equipment and machinery that are required by the sector.

in our company, we manufacture aluminum extrusion molds as well as press tools (such as Seal, Bolster, lnsert Bolster, Bolster Housing, Punch, Washer, Dummy Block, Sleeve, Knife). This production is carried out with high quality and desired tolerances using machine tools with CNC control units compatible with CAD-CAM software. The material hardening process is carried out in vacuum furnaces in the light of more than 30 years of experience from the leading companies of our country. The grain size and hardness specified by the standards are guaranteed for each product.

OUR SOLUTIONS

Die Design

Aydınsan Makina Aluminum Extrusion Molds design team designs with the guarantee of quality, long life and minimum testing in the light of customer suggestions and requests. The design process is developed taking into account the customer’s working conditions and expectations.

More

Production Technologies

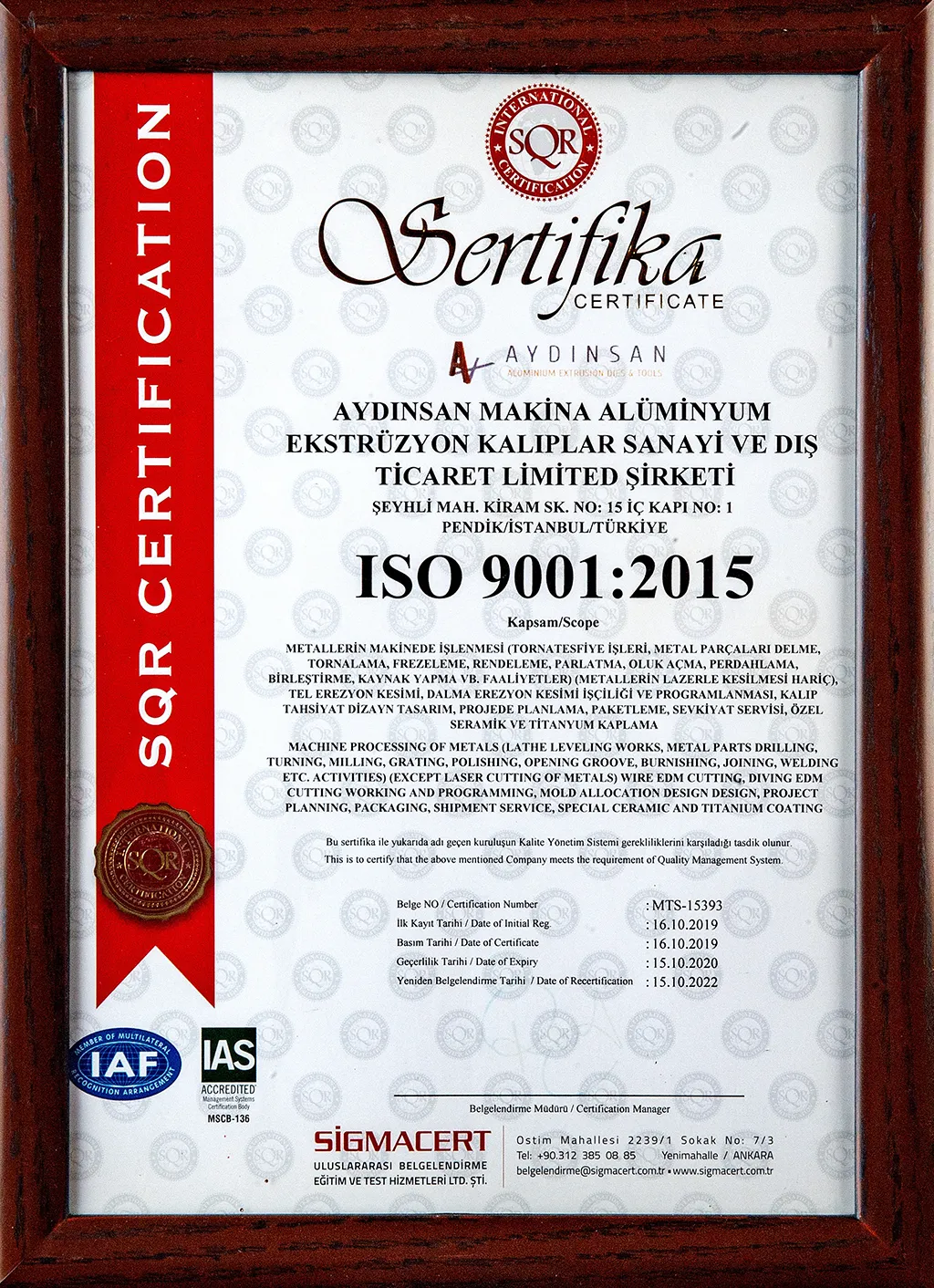

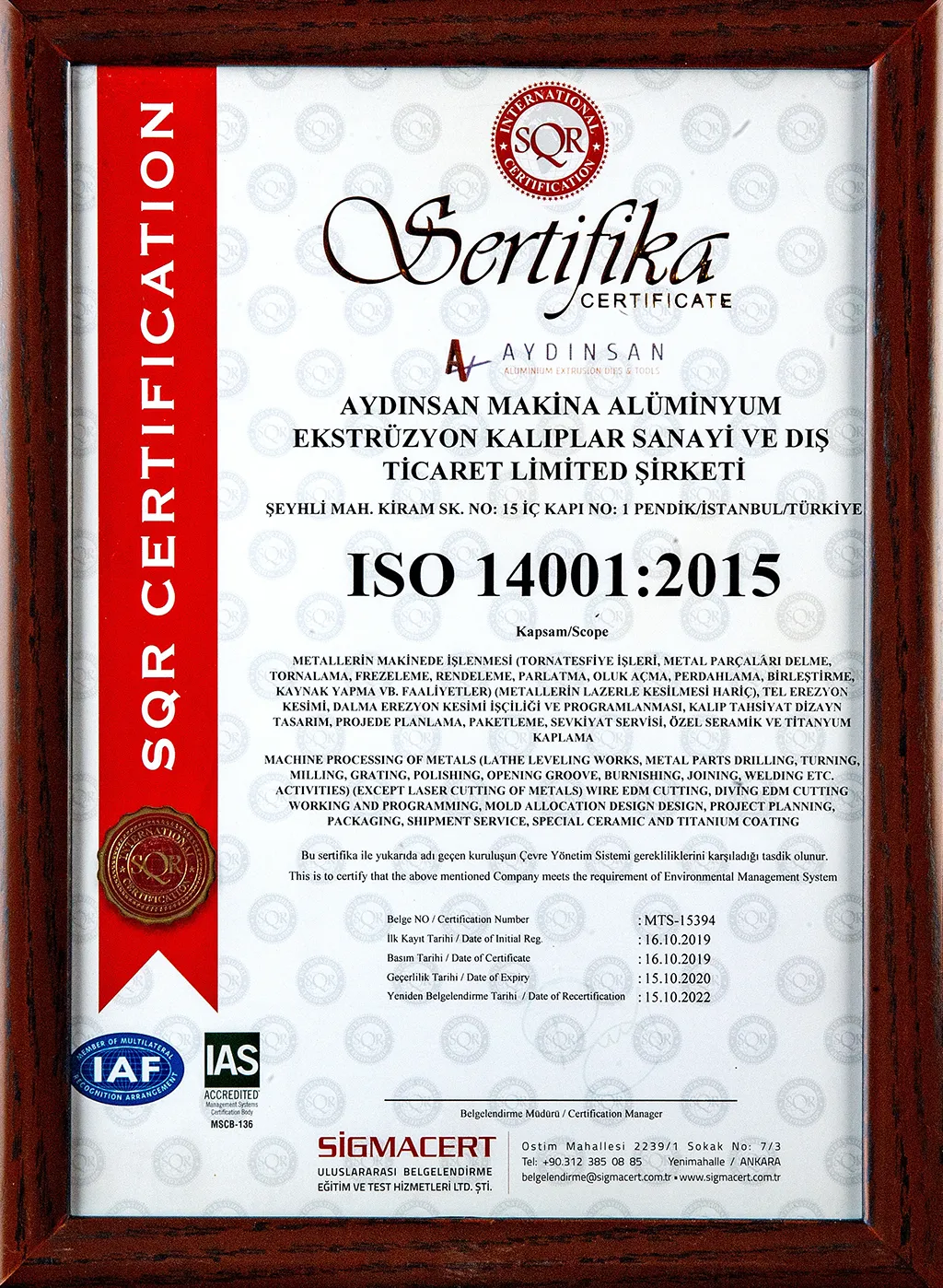

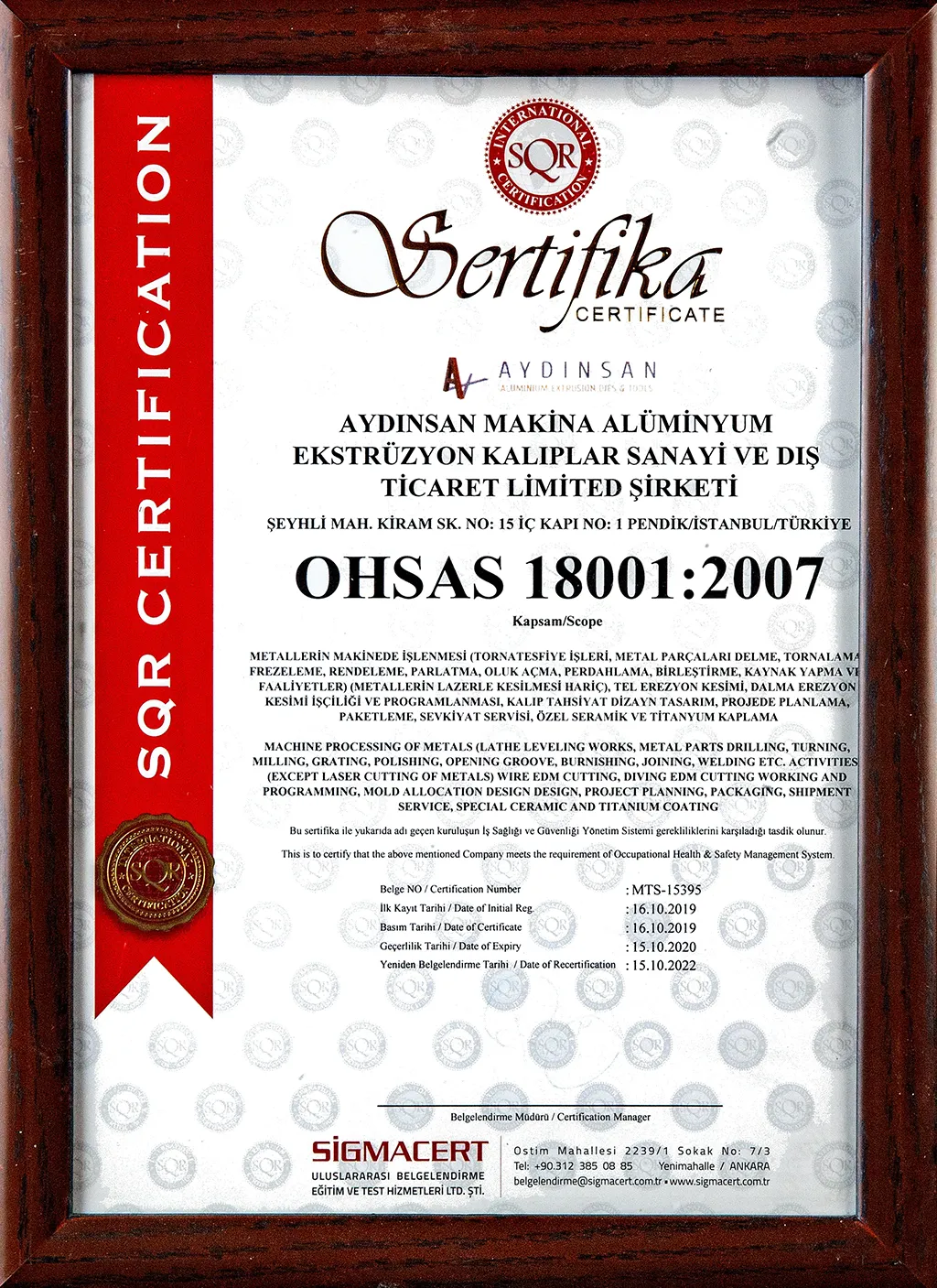

Now, the primary element of competition is not quality, but the dynamic quality approach. With this vision, we determine our quality policy by taking into account the demands of our customers, the warnings of experts and the findings of our employees.

More

High Quality

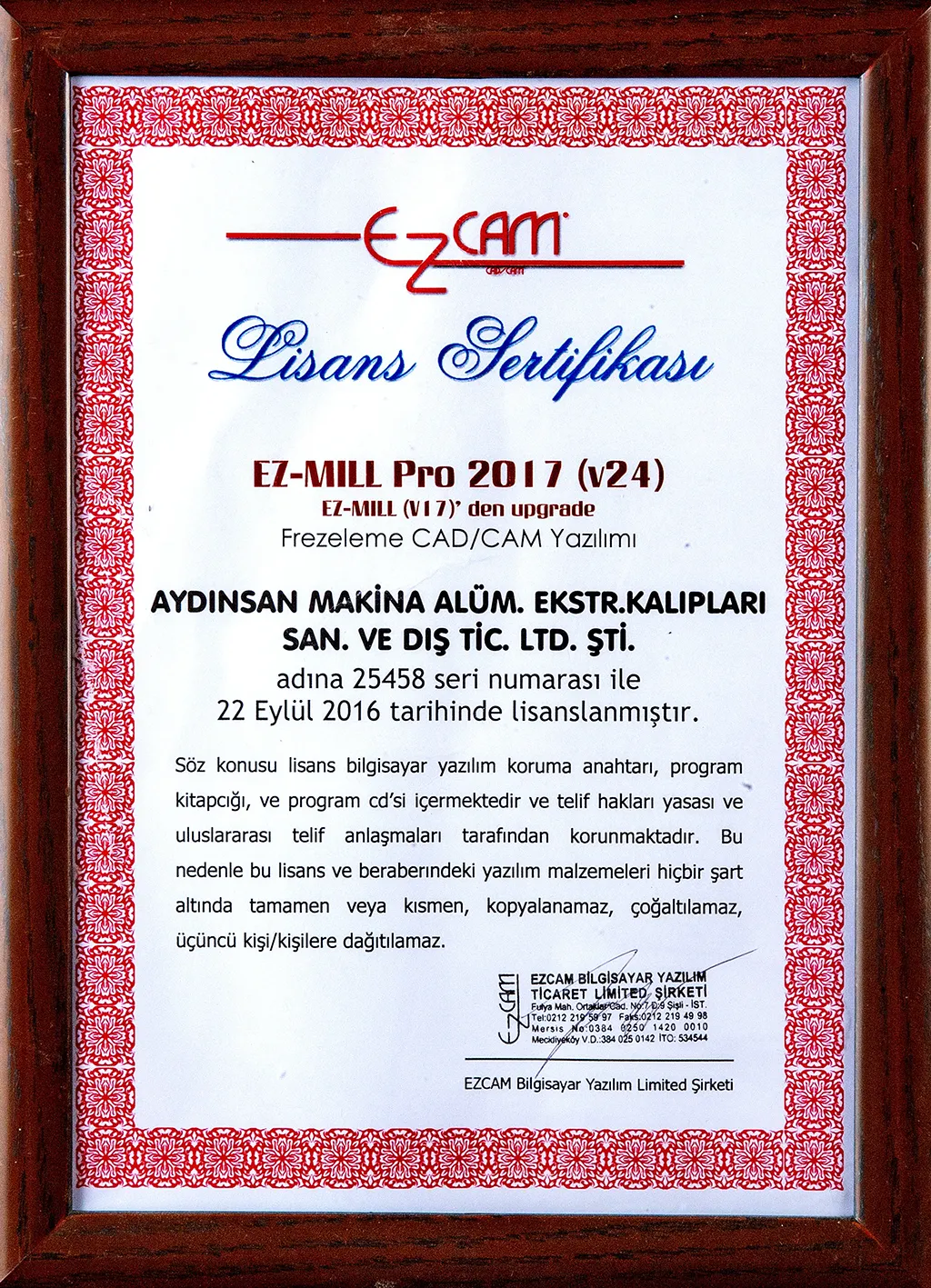

it is made in high quality and within the desired tolerances using machine tools with CNC control units compatible with CAD-CAM software. The material hardening process is carried out in vacuum furnaces in the light of more than 30 years of experience from the leading companies of our country.

More